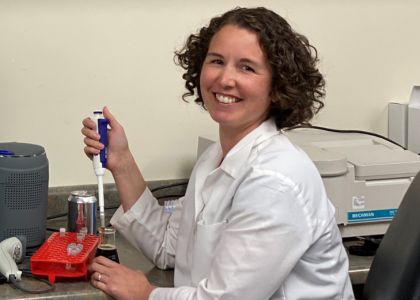

Grace Kennedy

Read about the perspective of Grace a Quality Assurance Technician at Zero Gravity to help you on your search and interview process!

What is your brewery story?

I started working at Zero Gravity in August of 2022 and prior to that I beer tended at a microbrewery, had a QA internship with Anheuser Busch, interned in a food allergens testing laboratory, and received a BS in Nutrition and Food Science.

What is your role at the brewery?

I’m a Quality Assurance Technician. I run a series of lab tests on our beer throughout the process of brewing and packaging to assess if it’s up to our set standards. That includes fermentation monitoring, microplating/microscopy/PCR, sensory analysis. I also do IBU and SRM testing.

What are the top things you would look for in hiring?

If I were to hire somebody I’d be looking for some type of brewery and or lab experience. I think experience can include but not be limited to a BS because in my case having a food science degree was really helpful.

What is your favorite part of your job?

The people I work with are my favorite part of the job. We have a good time here and many of them have been in the industry for a long time so I learn a lot from them. Something more job specific – I have the freedom and support to dive into projects and experiments that interest me. My most favorite part is the beer of course.

What is the hardest part of your job?

We brew a lot of different varieties of beer so keeping track of all the different regimens for each beer is challenging.

How have you seen your role grow?

I’m diving more into my interests within brewing which is really exciting. So I do daily lab tests and then I get to dive more into microbiology and projects with brewing yeast in my free time.

What is a typical day like for you?

In the morning I collect samples of beer that are fermenting and run them through a DMA/Alcolyzer which gives me AE and ABV data. From that I can compare that batch of beer to previous batches data and an established fermentation curve to see if it’s moving at an appropriate rate. We can also tell if it’s within our targeted ABV spec range and we can make changes to the hot side brewing process to adjust our fermentations. After that I look at microplates and see if there’s anything growing on different types of media. This tells me whether or not there are any microbes in the beer that could affect our product. If there’s something showing up on the media there’s another series of tests I can do to determine if it will spoil the beer or not. In the afternoon I plate things on different media depending on what it is and which step in the process it is. Those are my main tasks each day and then the rest of it is entering a lot of data into databases, some sensory tests, and a lot of maintenance and upkeep of a lab (making media, cleaning equipment and the space, etc.)

What would you recommend to someone who is hoping to work for a brewery in your field?

If they want to work in a brewery lab or QA I strongly recommend doing an internship in a lab setting if they haven’t already. It teaches you basic bench top techniques you’ll need to use. Also, get into brewery production if they can. Packaging, brewing, logistics, bar, etc. will help them familiarize themselves with how a brewery works and beer itself.